|

| August 18, 2015 | Volume 11 Issue 31 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox Deep Dive:

Advances in piezoelectric positioners for precision motion control in nanopositioning applications

Ever-increasing requirements for more precise motion control from the optics, biotech, and semiconductor industries have forced manufacturers of piezoelectric positioners to find ways to overcome their limitations, such as travel range and linearity, while preserving the unmatched speed, reliability, and resolution capabilities of piezoelectric devices.

By Stefan Vorndran and Scott Jordan, PI (Physik Instrumente) L.P.

Precision motion control in general, and nanopositioning in particular, are enabling technologies in many high-technology fields such as bio-nanotechnology, semiconductor test and measurement, optical alignment, nanoimprinting, scanning microscopy, and microlithography. Choosing the right nanopositioning stage depends not only on resolution and accuracy, but also on factors such as dynamics, size, the application environment, and cost.

A nanopositioning stage is a motion device capable of repeatedly producing motion in increments as small as a nanometer or less. There are several ways to achieve resolutions of one nanometer or below. Some may seem as simple as bolting a microstepped motor and a reduction gearbox to a leadscrew mechanism. More sophisticated approaches use additional position feedback in the form of an encoder and interpolator circuit. However, there is more to a nanopositioning system than a high-resolution motor.

The enemy is friction

Friction leads to hysteresis and induces guiding errors such as tilt and wobble. In most positioning systems, guiding errors are not measured, and hence remain uncontrolled. Tilt, wobble, and runout errors automatically contribute to positional inaccuracy. This fact is often neglected and rears its ugly head when several individual positioners are combined into one multi-axis system.

Friction is also inherent in traditional motor/leadscrew drive mechanisms. Even though such drives have been improved gradually over time and still provide many advantages for mainstream applications, for the most demanding applications in optics, semiconductor, and bio-nanotechnology fields the traditional approach is often not the answer. As the demand for speed and precision has kept going up, motion control systems manufacturers had to develop better options to keep pace.

Piezoceramic drive systems have always been known for their fast response and atomic resolution, though at limited motion ranges. Progress in piezo mechanisms, as well as control technologies, has solved the travel distance/precision conundrum. Scientists and motion engineers now have access to a number of piezo systems with virtually unlimited travel, without giving up stability, precision, and speed. (See Quick Guide box at end of article for more details on piezo actuator technology.)

Following are some motion control applications that have spawned the development of these new technologies:

Non-magnetic applications in semiconductor, scanning electron microscopy, and medical design

Positioning and alignment systems in e-beam lithography systems and scanning electron microscopy (SEM) can be equipped with electromagnetic drive mechanisms. However, the expense to shield them and/or position them outside of the action is very high, along with the increase in size. Fieldless piezo ceramic motors are significantly smaller, and can be positioned anywhere inside of these machines without causing negative effects.

Medical technology can also benefit from piezo solutions that have been optimized over many years for applications in semiconductor manufacturing and testing, and biotechnology research. Active ceramic components, such as piezo ceramic sensors and actuators, have already been used in medical design technology, for example in micro-pumps, ultrasonic transducers, fast valves for nano-dispensing applications, and for laser-beam control in eye and skin surgery.

For medical imaging applications, such as Magnetic Resonance Imaging (MRI) systems, ultra-high field imaging can have significant advantages for cardiac imaging. However, tuning of several coils in a whole-body scanner to achieve the best performance turns out to be a lengthy process. Replacing the manual tuning with computer-controlled non-magnetic piezo motors speeds up the process and provides better results at the same time, as shown in a recent paper by researchers at the Oxford Centre for Clinical Magnetic Resonance Research, Oxford UK, and the Center for Magnetic Resonance Research, Minneapolis, MN. (More information at "Automated tuning of an eight-channel cardiac transceive array at 7 tesla using piezoelectric actuators" http://onlinelibrary.wiley.com/doi/10.1002/mrm.25356/full).

3D-optical microscopy, and Optical Coherence Tomography (OCT), can also benefit from piezo drives due to their high efficiency, direct-acting linear motion, high resolution, fast response, and non-magnetic characteristics.

Nanometer precision in scanning microscopy -- small ranges, but very high throughput

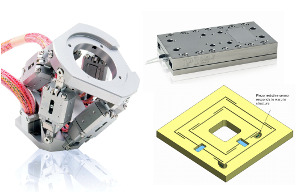

In modern drug-discovery applications, a multitude of samples have to be examined in the shortest possible time. Techniques such as fluorescence imaging are employed and require precise focusing on small amounts of liquid, usually held in multiwell plates (See figure 1).

For long-range well-to-well positioning, conventional electric motors or voice-coil drives typically can provide the required speed and precision. Still, the focusing is best achieved with frictionless, piezo flexure stages or objective positioners. Response times on the order of a few milliseconds allow extremely fast focusing and thus rapid data acquisition. The fast response also reduces the risk of photo bleaching caused by long-term exposure.

Figure 1. Fast-focusing piezo flexure positioners: objective scanner (left) and well plate scanning stage (right) deliver high-throughput screening in drug-discovery applications.

Similar speed/resolution requirements are prevalent in near-field scanning optical microscopy (NSOM). Here, small samples are scanned, typically 100 x 100µ to 500 x 500µ, with nanometer lateral resolution. To minimize the scanning time and achieve the high resolution required, flexure-guided piezo stages are the only option. The latest designs employ a parallel-kinematic motion principle, with all actuators acting on one moving central platform, greatly reducing inertia for much-improved dynamics. Capacitive sensors integrated into the stage take multi-axis measurements against a common fixed reference (parallel metrology). This approach allows drift-free positioning with nanometer straightness -- not available with classical stacked/nested multi-axis designs.

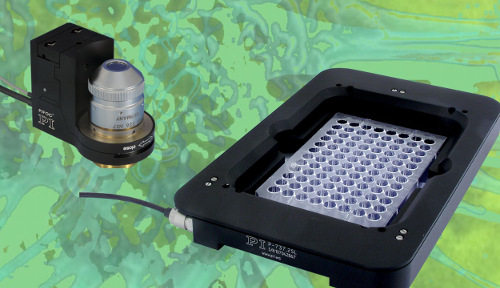

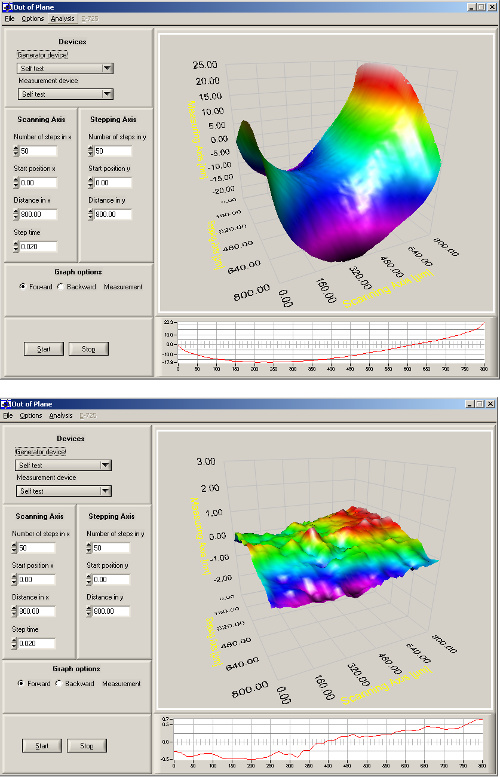

The same approach yields superior surface metrology results in atomic force microscopes (AFM). Progress in semiconductor development heavily relies on materials testing, and an AFM's output data is only as good as the out-of-plane motion (OOPM) of the XY scanning stage it employs. Here, traditional bearings are totally out of the question, and the requirements have been pushing the mechanical limitations of the best flexure designs. Active trajectory control approaches (compensating minute off-axis errors with integrated piezo transducers) now provide OOPM in the sub-nanometer realm, over large scanning areas to hundreds of microns (See figure 2).

Figure 2. Improved out-of-plane motion of AFM scanner with active trajectory control.

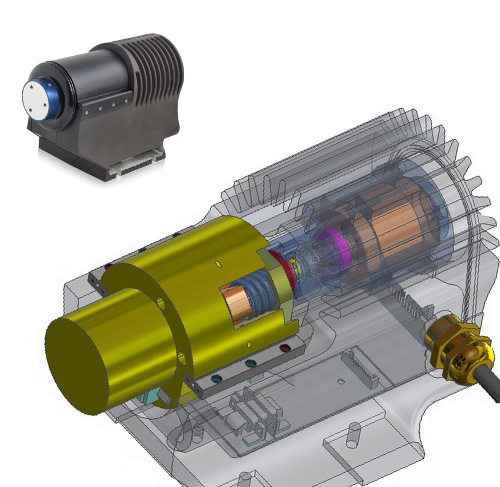

Nanopositioning goes hybrid: Looking at the stars

Hybrid positioning systems combine the best of two worlds: long travel ranges with low power requirements, and sub-nanometer resolution with very high dynamics. Progress in controller design has made possible real-time closed-loop control of an actuator consisting of a piezo-flexure arrangement in series with a servo-motor/ballscrew assembly. The controller reads the stage position from an integrated, sub-nanometer-class linear encoder and continuously coordinates both the piezoelectric and servo-motor drives simultaneously in a way to provide the best possible overall performance, with rapid pull-in, nanometer-scale bi-directional repeatability and inherent axial stiffness. The actuator (See figure 3) has been proposed to drive the European Extremely Large Telescope (E-ELT) -- a 39-m-diameter next-generation telescope, segmented in 800 hexagonal mirrors. The combined motion of the frictionless piezo and the screw drive provides unprecedented smoothness and accuracy, even beating the required 1.7nm RMS tracking precision. One has to consider, that under operating conditions the load on the actuator changes in a range of zero to 900N. When the telescope tracks the stars, all 800 segments have to stay aligned perfectly as not to distort the wavefront of the incoming light. Under laboratory conditions, better than 0.8nm RMS tracking accuracy was achieved. (additional information is available at www.aspe.net/publications/Short%20Abstracts%2013A/3763.pdf).

Figure 3. Hybrid nanopositioning actuator as proposed for the E-ELT telescope combines the advantages of piezo flexure drives and ballscrew drives.

High-force, piezo-walk linear motors

High-energy physics experiments often require components to be insensitive to strong magnetic fields and EMI. An ideal scenario for a motion-control device would be to hold a position exactly when powered down. A new robust piezo motor based on the piezo-walk principle is now available to provide backlash-free, highly stable motion over centimeters of travel with nanometer resolution. Due to the self-clamping design, no power is dissipated in steady state, and a position can be locked into place even when the controller is powered off.

The piezo-walk principle is based on coordinated motion of several longitudinal and lateral piezo actuators arranged about a central ceramic runner. A digital controller sequences their operation, providing high-force, long-travel step-mode actuation plus picometer-resolution high-bandwidth actuation. This type of piezo motor can generate forces to 170 lb, and is also vacuum-compatible and fieldless, with nanoscale power-off position stability for months.

Compact piezo walk motors can be integrated in low-profile linear translation stages (See figure 4) such as used in laser tuning and aligning applications. They combine long travel motion with a highly dynamic short-range sweep mode.

Figure 4. Low-profile linear translation stage based on miniaturized piezo-walk motor provides 1-in. travel and sub-nanometer resolution.

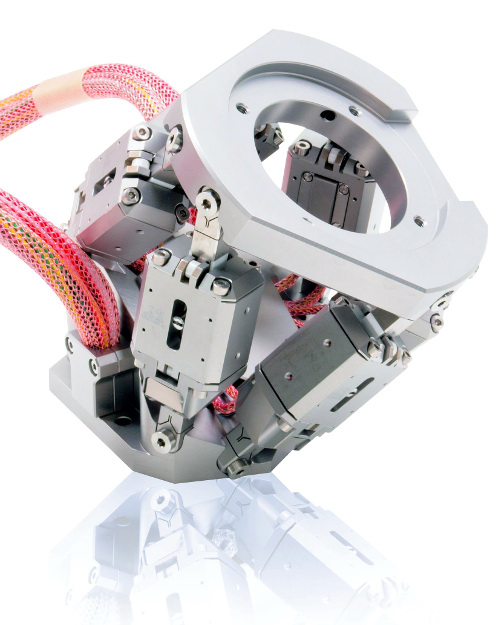

Multiple piezo motors can be arranged to form compact hexapod 6-axis positioners (See figure 5). The hexapod approach, with its virtual pivot point and central aperture, is crucial for optical alignment problems as large as secondary mirrors in the latest-generation earthbound telescopes, and as small as fiber-to-photonic-component alignment in telecommunication chips.

Figure 5. Miniaturized hexapod nanopositioning system based on non-magnetic, UHV-compatible piezo-walk motors, provides precision motion in 6 axes.

Eliminating the travel/resolution tradeoff of traditional piezo flexure positioners

Classical piezo flexure positioners excel through their frictionless, guiding systems, rapid response in the kHz range and extremely high reliability. Piezo flexure actuators have passed 100 billion cycles of life testing by NASA/JPL for the Mars Mission and are currently in use on the Curiosity rover. The motion of a piezo flexure actuator is roughly proportional to the applied voltage, often generated by a digital-to-analog converter (DAC) driving an amplifier. In recent history, piezo flexure motion was limited to approximately 100 microns, but advances have pushed the limits to beyond the millimeter range. The number of addressable positions for such a piezo mechanism is 2b -- where b is the bit-width of the DAC's digital input. In order to cover longer travel ranges while maintaining nanometer resolution, DACs with more bits were the only solution. A patented technology called HyperBit now leverages the under-utilized time-domain capability of today's DACs, converting it into up to 11 additional bits of physical positioning resolution. In a recent digital-based servo-control system for X-ray interferometers, 5 picometers (10exp -12m) positioning resolution was achieved using this novel technology.

Nanopositioning sensors

High-accuracy position feedback is essential in a good nanopositioning system, and direct motion metrology is the preferred choice. Direct metrology measures motion where it matters most to the application. Examples of high-resolution, direct metrology sensors are capacitive sensors, laser interferometers, and non-contact optical, incremental encoders.

Laser interferometers are capable of accurately measuring long distances, and some provide sub-nanometer resolution, although bulky optics must be mounted onto the moving elements of the motion system.

Optical encoders are more compact and rely on diffraction between a moving reticle and a scale composed of finely pitched lines. Position is determined by counting fringes and interpolating between individual peaks, similar to interferometry. The latest linear encoders can provide resolution in the 100-picometer range. Interferometers and incremental optical encoders are relative position sensors that must be initialized at a reference position. The stability of this reference position also influences the overall precision. While not yet common, high-resolution absolute encoders break the nanometer barrier but are still held back by high cost and more complex interfacing.

For travel ranges of less than 1 mm, capacitive sensors have emerged as the default choice. They are compact, high-bandwidth, and absolute measuring devices providing sub-nanometer resolution. For less demanding applications, strain gauge sensors (piezoresistive sensors) are a good alternative.

Piezo-driven mechanisms achieve accuracy and repeatability by integrating position feedback sensors.

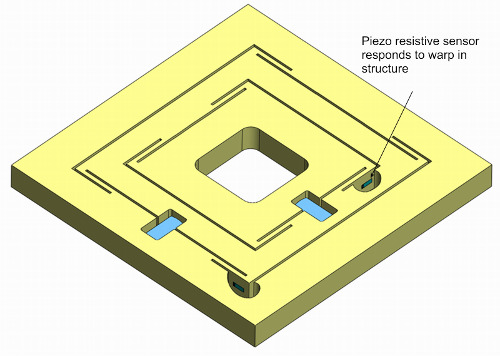

Piezoresistive strain gauge sensors (PRS) are economical, but temperature-sensitive, devices that are easily integrated in positioning devices. They are glued to the flexure structure or piezo stack, but the extra layer of epoxy between the sensor and structure makes it a challenge to get sufficient long-term stability. PRS do not measure distance directly, but infer position of the moving platform from the nanoscale warping of the structure (See figure 6). Due to the indirect measure of position, inaccuracies can occur and orthogonality errors are unobservable. Calibration to an interferometer allows them to achieve adequate accuracies for classical microscopy applications. Since their output signal is a low-voltage DC current, the derived position can be more susceptible to noise pickup and drift.

Figure 6. Multiaxis piezo flexure stage with piezoresistive sensors infer position information from the strain/flex of a strut, piezo stack, or a flexure guide.

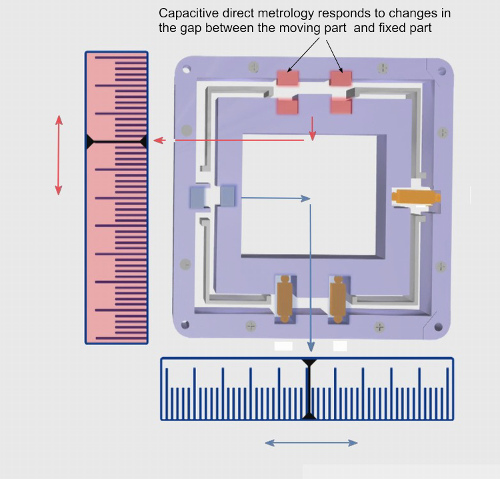

Capacitive sensors are high-value sensors composed of diamond-machined plates that directly measure the absolute position of the stage platform (See figure 7). Traditionally deployed in high-end semiconductor manufacturing tools and advanced microscopy applications, such as single-molecule studies, capacitive sensors provide especially precise, accurate, and fast position metrology. Since the stage platform is measured directly, cross-talk and orthogonality can be eliminated. Since no glue is used to attach the sensors to the platform, they are exceptionally stable and reproducible and are usually calibrated to 4th order or higher. Their tightly controlled RF signal is consequently robust against noise. Their inherent stability makes them an ideal fine-positioning companion to ultra-stable piezo motor long-travel coarse-positioning stages.

Figure 7. Piezo flexure stage with dual-plate capacitive sensors provide non-contact, direct measurement of the moving platform in reference to the non-moving frame.

Assessing the right nanopositioning option

Piezo ceramic motion systems have long been the No. 1 choice for ultra-high precision motion. With ever-increasing requirements from the optics, biotech, and semiconductor industries in recent years, manufacturers were forced to find ways to overcome limitations such as travel range and linearity, while preserving their unmatched speed, acceleration, and resolution capabilities.

With the abundance of choices available today, it is more important than ever to understand the user's application, and its requirements on dynamics and precision, as well as the control and interfacing preferences of the user. Making the right choice in nanopositioning involves assessing multiple criteria. But if the user is willing to do a bit of research, and engage in a dialog with a credible manufacturer, the result will be a significant step forward from what was feasible just a few years ago.

------------------------------------------------------

------------------------------------------------------

Quick guide to different types of piezo motors and actuator systems

All piezo motors and actuators are intrinsically vacuum compatible and non-magnetic.

A) Simple Piezo Actuators (Stack, Tube, Shear, Bender)

Expand proportionally to the applied voltage, travel range up to 0.2 percent of actuator length.

Features:

- High force available, to thousands of kg;

- Very fast response -- microsecond to millisecond range;

- Frictionless, sub-nanometer resolution;

- Travel range typically 10µ to 200µ for stacked actuators; 3 mm to 4 mm for (low force) bender actuators;

- Closed-loop operation with feedback sensor for higher linearity.

Sub-Groups:

- Stacked Actuators: (most common): Available in co-fired multilayer construction (typically 100 V); and classical design (stack of discrete PZT disks/electrodes, 500 V to 1,000 V). High force, motion typically up to 200µ. Also available with aperture.

- Shear Actuators: Lateral motion, allows design of small, very fast XY and XYZ positioners, also used in piezo stepping motor designs. High force, travel typically limited to 20µ.

- Tube Actuators: Often used in microdispensing (pump) applications and as scanner tubes for AFM microscopy. Very fast response (very low inertia), low force (fragile), travel range typically <20µ. XY scanner tubes available.

- Bender Actuators: Available in multilayer construction (60 V); and classical (bimorph) design (200 V to 1,000 V). Low force (< 1 kg), very long deflection (to several millimeters), relatively slow response (approximately 10 msec).

B) Piezo Flexure Actuators/Positioners (flexure-guided, piezo stack-driven nanopositioning and scanning stage or actuator)

These more complex systems use frictionless flexures and motion amplifiers to provide extremely straight and flat motion, and often longer travel than can be accomplished with simple piezo actuators. For the highest accuracy, integrated capacitive position sensors provide sub-nanometer precision in multiple degrees of freedom.

Features:

- Frictionless, fast response (0.1 millisec to 10 millisecs), sub-nanometer resolution feasible; scanning frequency up to kilohertz range;

- Integrated multiaxis-systems available;

- Internal motion amplifier provides typical motion range up to 2,000µ;

- Essential for nanoalignment, scanning optical microscopy, and nanomanipulation;

- Position feedback sensor can be integrated (typically strain gauges for entry level, or capacitive for high-end systems and independent multi-axis measurements).

For A and B, the motion is basically proportional to the DC output voltage of the piezo driver/servo controller. A position feedback sensor is required for linearization, due to the nonlinear behavior of piezo material.

The piezo actuators/motors use different types of controllers, and typically, incremental feedback sensors.

C) Ultrasonic Motors

Features:

- Based on high-frequency oscillation of a piezo plate (stator) at the nanoscale;

- Oscillation is transferred to a slide or rotor via micro-friction;

- Unlimited motion range, high speed (to 1000 mm/sec in some of the latest designs), fast response (10 to tens of millisecs);

- Resolution typically 10 to 50 nanometers. Forces, typically 2N to 10N (0.5 to 2 lb);

- Power-off, position-hold capability;

- Small amount of particle generation due to friction.

D) Piezo Stepping Motors (PiezoWalk) such as PI NEXLINE Drive

Features:

- Virtually unlimited motion range;

- Based on accumulation of small, highly controllable steps;

- Picometer resolution by means of direct piezo actuation (linear mode, dither mode);

- Compact and high force to 170 lb (for off-the-shelf units),

- Significantly lower speed than ultrasonic motors (1 to 10 mm/sec);

- Fast response (< 1 millisec feasible), very high stiffness;

- Drift-free power-off, position-hold.

E) Piezo Inertial Motors (Stick-Slip Motors) -- Very compact, motion-based on the stick-slip-effect

Features:

- Most economical and compact design;

- For applications that require slow motion and low force;

- Challenging closed-loop control;

- Not recommended for applications that require constant velocity.

About Scott Jordan

Scott Jordan is Director of NanoAutomation Technologies for Physik Instrumente L.P. A physicist by training with an MBA in New Venture Management and Finance, he publishes frequently on nanotech developments, including novel instrumentation, software, and microscopy techniques.

About Stefan Vorndran

Stefan Vorndran is VP of Marketing at Physik Instrumente L.P. He holds a Dipl. Ing. degree in electrical engineering from University of Darmstadt/Dieburg, Germany.

About Physik Instrumente L.P.

Physik Instrumente L.P. (PI) is a leading manufacturer of nanopositioning, linear actuators, and precision motion-control equipment for photonics, nanotechnology, semiconductor, and life science applications.

For more information please contact Stefan Vorndran, VP Marketing for Physik Instrumente; 16 Albert St., Auburn, MA 01501; Phone 508-832-3456, Fax 508-832-0506; email stefanv@pi-usa.us; www.pi-usa.us.

Published August 2015

Rate this article

View our terms of use and privacy policy